Bulk solids in production and logistics

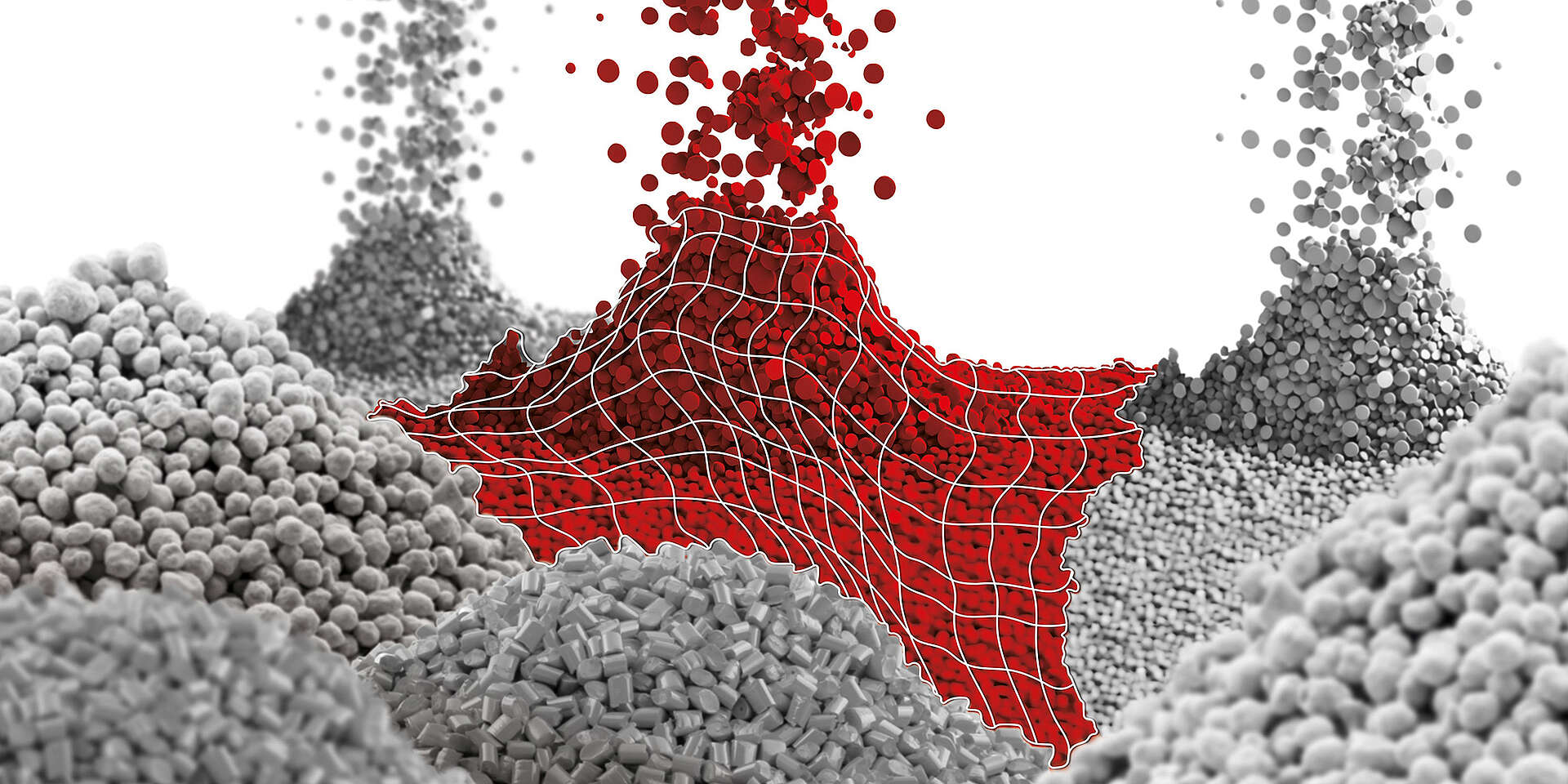

Bulk solids are loose, powdery, granular or lumpy solids that are required for many production processes. These include natural substances, building materials, foodstuffs, powders, granulates or raw and auxiliary materials for the chemical industry. The mixtures are either transported openly in skips, in bags or in closed silo vehicles and ships and stored in large storage facilities, bunkers and silos.

Suitable, permanently installed measuring instruments are required for inventory control of the storage containers used, which reliably indicate the fill levels of the bulk solids - because depending on the moisture, grain size, grain distribution, bulk density, angle of repose, temperature and frictional resistance, the mixtures behave very differently when being poured, stored or discharged from the storage container. Their flowability in particular depends on these parameters.

Because bulk solids move freely in the storage containers and are not further secured within them, the flow behaviour must be monitored closely. When stored in high silos, permanently installed fill indicators, demand indicators or empty level indicators ensure reliable stock control.

MBA Instruments offers proven solutions for level measurement that are not only precise and reliable, but also meet the special requirements for the storage of bulk solids.

Request advice

Abrasive, cohesive, floury, fine-grained or free-flowing - these are just some of the possible bulk solids characteristics. This is because raw material mixtures differ depending on their origin, chemical composition and grain size. Knowledge of their density, air retention capacity, flow behaviour and friction ratios is essential for bulk solids handling.

The processing of bulk solids and their storage play an important role in almost all branches of industry today. This applies both to coarse bulk solids for the construction industry and natural materials for the glass and ceramics industry as well as to powders with grain sizes in the nanometre range, which are required in the chemical and pharmaceutical industries.

Bulk goods include, for example, ores, clay and coal or building materials such as gypsum, sand, gravel and cement. Basic chemical materials such as granulates, pellets and pigments also fall into this category, as do foodstuffs such as salts, sugar, flour and coffee. Bulk solids are often filled into silos to store them until they are used.

What sounds simple in theory is quite challenging in practice: when filling bulk silos, the bulk load, stresses in the hopper, the silo design and the flow profile (mass flow or core flow) as well as the angle of repose must be taken into account, among other things.

In addition, bulk solids can have fluctuating material properties, such as moisture, or solidify over time.

Depending on the type, structure, grain size and composition of the bulk solids, environmental effects such as dust pollution may occur. In some cases, explosion protection regulations must be taken into account. It is therefore of the utmost importance to carefully specify bulk solids before handling and storage.

Important distinguishing features include

- Flowability

- Bulk density

- Grain size

- Particle size distribution

- porosity

- temperature

- Moisture content

The distinction between two main groups of bulk solids, cohesionless (free-flowing) bulk solids and cohesive (cohesive) bulk solids, plays a decisive role in the handling and transport of these materials.

Carriage and transport

Bulk solids are materials that, as the name suggests, are pourable. They are usually transported loose. They are loaded using conveyor belts or tipping devices.

Depending on the type of bulk solids, various load carriers and means of transport can be used for the actual transport. The type of bulk solids determines the form of the means of transport. Bulk freight can be transported overland by road and rail. Silo vehicles, walking floor vehicles or tipper vehicles can be used for road transport. In sea and inland waterway transport, bulk goods are transported in special bunkers or bulk goods rooms.

While bulk solids, such as gravel or coal, can be transported openly in skips, soluble goods (e.g. salt, sugar, etc.) require transport in silos.

Bulk material types

Different bulk solids are used depending on the field of application. These bulk solids vary not only in their composition, but also in their properties and areas of application. A precise knowledge of these bulk material types is crucial in order to develop the optimum solutions for handling, storage and processing.

Building materials form the basis for the design of our inhabited living spaces. In order to meet the requirements for certain construction applications, bulk solids must fulfil certain requirements in terms of load-bearing capacity, frost or weather resistance, filter properties, cohesiveness, compaction or tilting. Building materials in pourable form include gypsum, sand, gravel and cement.

Bulk solids comprise a variety of mineral resources such as ore, clay or coal. Due to geological conditions, they are site-specific and not evenly distributed across the country. Due to their chemical and physical properties, raw materials are used in particular in the paper, chemical, glass, ceramics, refractory, foundry and steel industries.

In the chemical industry, bulk solids in various forms are produced or used as raw materials (e.g. as granulates, pellets or pigments). An important area within these bulk material types are fillers, which play a decisive role in many chemical processes.

Fillers are substances that are used to modify or improve the properties of materials. They are often used as additives in polymeric materials, paints, varnishes, adhesives, concrete and other products.

Level measurement method from MBA Instruments

Our portfolio offers an extensive range of products for the level measurement of bulk solids in demanding applications. This includes a selection of approved fill level technologies. Depending on the material and production process of the bulk solids, different measuring methods can be used.