Continuous measurement of conductivity in flowing light oils

Continuous conductivity measurement is considered a key technology in industry, research and environmental monitoring. Our exclusive sales partner FAUDI Aviation is your expert for all aspects of continuous conductivity measurement in light oils. Our expertise consists of industry and application specific know-how. From the selection of suitable measuring devices to implementation and maintenance, we offer a holistic approach that ensures your processes run efficiently and safely.

Comprehensive support is provided throughout the entire lifecycle of your equipment and processes.

Principle of measurement of continuous conductivity measurement

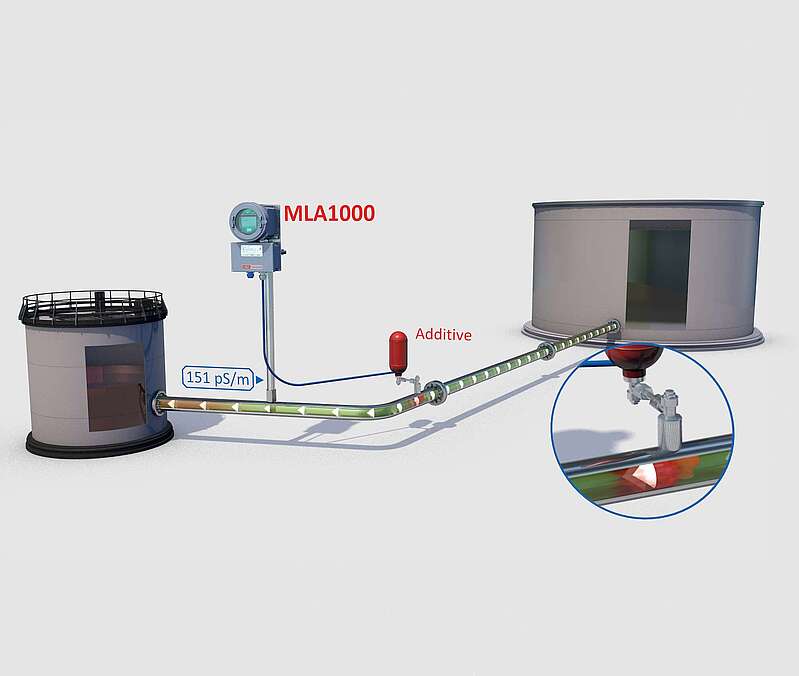

Continuous conductivity measurement is carried out by inserting special sensors or probes into the liquid flow. The sensors continuously measure the electrical resistance of the liquid as it flows through the pipe. Based on the measured values, additives can be added according to the principle "as much as necessary - as little as possible".

The measured resistance is then converted into conductivity. This enables continuous monitoring of conductivity throughout the process, which is important in many industrial applications and production processes.

How it works in a nutshell:

- Flow of paraffin through the pipework

- Measurement of conductivity with a measuring device in the pipeline

- Comparison of the measured value with the target value; possible control of the additive supply

- Injection of the required quantity of additives

The main difference between continuous conductivity measurement and mobile conductivity measurement lies in the way the measurements are carried out and the context in which they are used. With mobile conductivity measurement, the conductivity is measured at longer intervals using individual laboratory samples or measuring devices. The dosage of the necessary additives is then often only estimated. Mobile conductivity measurement makes it possible to carry out conductivity measurements at different locations as the measuring device is portable and mobile.

Continuous conductivity measurement, on the other hand, aims to monitor the conductivity of a liquid during the continuous operation of a system. By continuously controlling the additive dosing, the conductivity of a product cannot fall below a certain level. This ensures that, on the one hand, the safety-relevant concentration of additives is not undercut and, on the other hand, that the maximum conductivity value specified for optimum operation is not exceeded.

Both methods have their advantages and are used depending on the specific requirements and areas of application.

Further areas of application

Continuous conductivity measurement is used in various application areas, especially in industry and research. In scientific research, continuous conductivity measurement plays a role in a variety of studies, whether in chemistry, biology or environmental science. It helps researchers to accurately monitor and understand changes in solutions or environments.

Send enquiry

Would you like to find out more about MLA1000?

FAUDI Aviation GmbH is the exclusive distribution partner for MLA1000 conductivity meter. We are here to assist you and advise you on all orders and requests regarding MLA1000.

We look forward to hearing from you and will get back to you as soon as possible.