Point level detection in bulk storage silos

Our level switches have proven their worth for measuring point levels in silos for granulated bulk solids.

Due to their robustness and functional reliability, the switches are particularly suitable for use in storage silos with aggressive atmospheres and high temperatures. Many years of experience make our level switches the preferred level measuring technology for chemicals, food or raw materials such as sugar, salt, grain, lime, pellets and cement.

We are the inventors of the rotary paddle - the standard for point level measurement. Interested in our products?

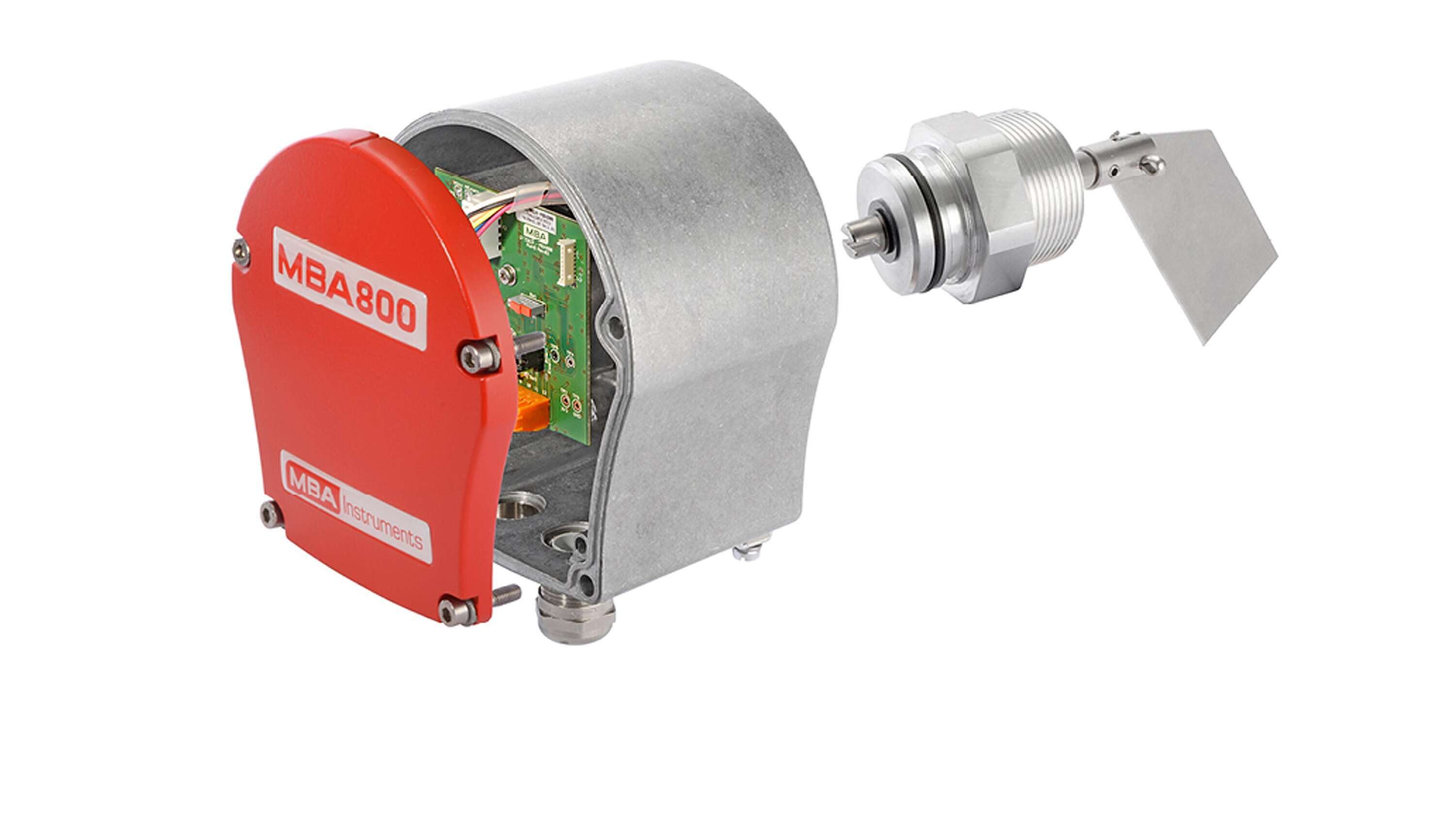

Rotating paddle detector

Robust, ready for use and precise. The rotating paddle detector series from MBA with state-of-the-art safety technology and various paddle options is as reliable as it is versatile. Depending on the individual requirements, they are used as full, on-demand or empty detectors in silos, hoppers and process containers.

Membrane switch

The maintenance-free membrane switch from MBA fulfils central tasks in the point level measurement of free-flowing bulk solids such as granulates, powders or pellets. The purely mechanical level switch is particularly user-friendly in its handling. Simply attach it to the silo wall and connect it to the signalling cable to put the membrane switch into operation.

Simple and safe point level detection

Our level switches determine the predefined fill level in a silo or tank.

Point level switches can be integrated into a process control system using a binary signal. This type of level measurement is used when not all possible intermediate levels need to be measured. In most cases, they act as on or off switches that activate a function when a certain level is reached in the tank or silo. This may involve triggering an alarm or switching on a device.

Point level detectors recognise media at a predefined position. The sensors are mainly used as full or empty detectors in the upper or lower area of the process containers to prevent overflowing or complete emptying.

If a certain fill level is particularly relevant, the devices can also function as demand detectors.

Measuring point levels in bulk solids and liquids requires a deep understanding of the specific process conditions.

One of the main challenges is to take into account the variety of media and environments in which these measurements take place.

Different densities, viscosities and electrical conductivities of the media require flexible and adaptable measurement methods. Different densities, viscosities and electrical conductivities of the media require flexible and adaptable measuring methods. Temperature fluctuations are also unavoidable in many industrial processes.

They can change the density of liquids and impair the performance of sensors.

Overcoming these challenges requires not only sophisticated technology, but also a willingness to co-operate between point level instrument manufacturers and end users.

At MBA Instruments, we are committed to providing our customers not only with world-class products, but also with the comprehensive support and expertise to successfully meet these challenges.

We are committed to continuous research and development to create solutions that meet the ever-changing needs of our customers.

Mechanical processes in our company must be constantly adapted and improved in the interests of sustainability. This is only possible with flexible and always highly efficient measuring instruments. It's good to know that we can always fully rely on MBA Instruments.

Giso Richter, Company Electrician, Karl Bindewald GmbH

Areas of application in the process industry

The primary objective when processing products is consistent product quality.

In order to achieve this, high demands are also placed on the measurement technology used. Point level measurement is generally intended for processes in which high or low fill levels need to be monitored.

The point level switches are used as overfill protection, empty detection and dry run protection in various branches of industry to monitor empty and full levels.

Typical areas of application for level detection in the process industry are storage tanks, silos, pipelines or overflow basins. Point level switches are usually used in liquids, pasty media, light and heavy bulk solids.

Depending on the principle of measurement, point level measurement is also used in abrasive and adhesive media, in the food and pharmaceutical industries and under extreme temperature and pressure conditions.

MBA - Your partner for precise measurement results

Precision and unambiguity are the fundamental challenges of level measurement that MBA has been successfully solving for more than 50 years. Optimised for special requirements and applications, MBA's level measuring devices can be used in a wide variety of goods and containers - for reliable measurement results and precise action triggers.

The basis for precise level measurement: proven technology and many years of experience

From bucket elevators and storage silos to hoppers, ship loaders and transfer stations: Our technologies in the field of level measurement are characterised by coordinated measuring principles and the greatest possible scope for your applications.

Talk to us about your requirements!