Level measurement with radar sensors, ultrasound or plumb bob

Level sensors enable continuous real-time detection of the precise fill level of a medium.

The so-called level sensors detect the exact height of the fill level in a silo, display it on site or integrate the measured value into a process control system. Various technologies and measuring methods can be used.

Find out more about level measurement with radar, ultrasound, solder and capacitive level measurement. We would be happy to advise you on customised solutions.

Contact us

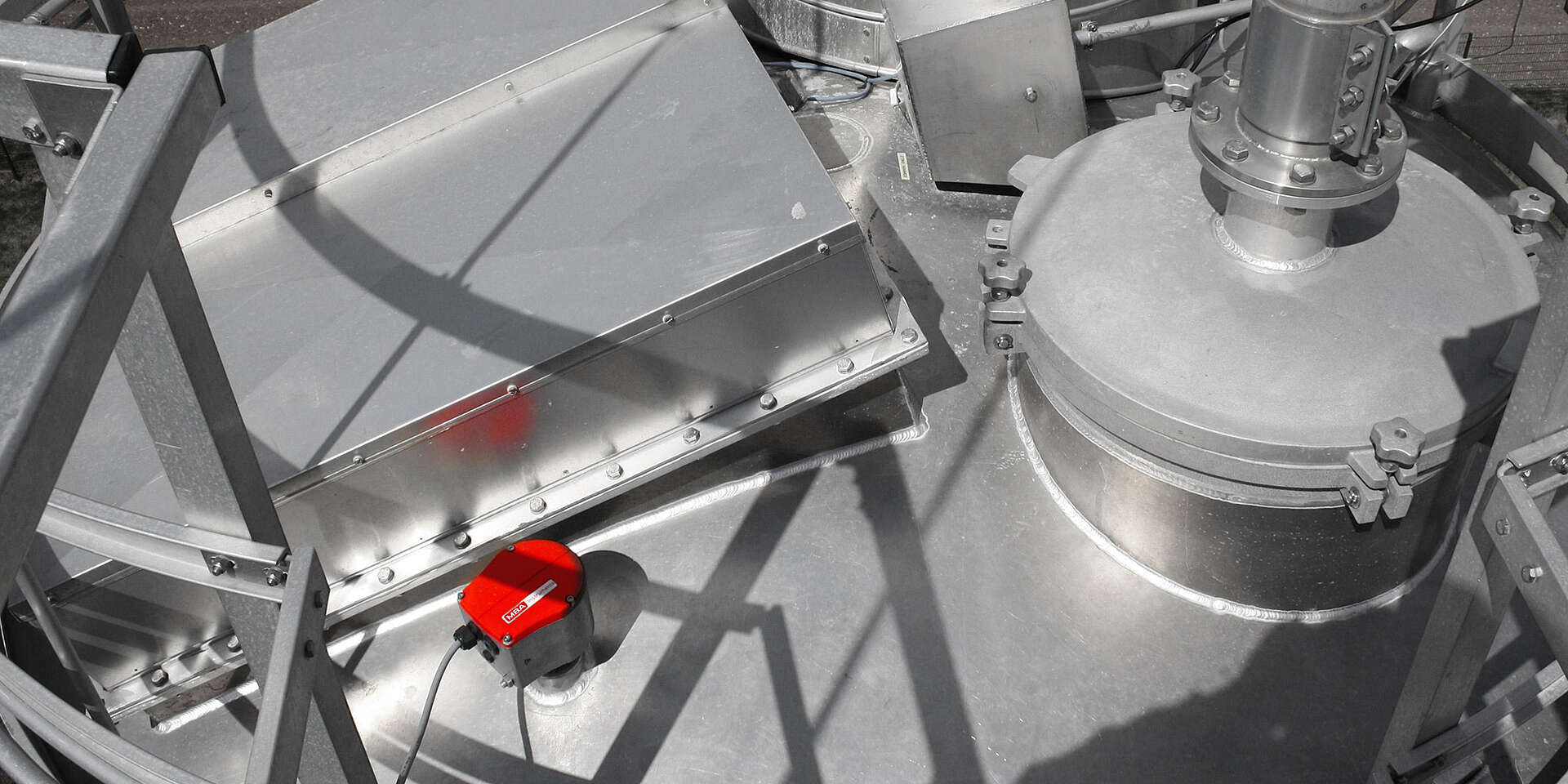

Level measurement with radar sensors

In non-contact level measurement using radar, microwave signals are sent from above onto the product in a silo and reflected by it.

By analysing the microwave signals, the measuring device determines the distance to the surface of the product and uses this to calculate the fill level.

Level measurement with radar is suitable for bulk solids, but is prone to errors. We have described the advantages and disadvantages of this measuring method here:

Level measurement with ultrasonic sensors

In ultrasonic level measurement, the sensor sends ultrasonic pulses in the direction of the product, which are then reflected by it.

The time required to send and receive the signals is directly related to the fill level in the container.

Ultrasonic sensors are suitable for standard applications, but there are better alternatives. Find out more:

Level measurement with capacitive sensors

Capacitive level measurement uses a capacitive sensor and the container itself as the electrodes of a capacitor.

When the fill level changes, this leads to a change in capacitance, which is then converted into a fill level signal.

Capacitive sensors can recognise solid, liquid or granular objects. Capacitive sensors can also be used reliably in very dusty or dirty environments.

Find out whether this measuring method is suitable for your application:

Level measurement with plumb bob sensors

Level measurement with an electromechanical pumb bob is based on a belt or rope reel that is driven by an electric motor and to which a sensing weight is attached. The sensing weight can be adjusted to the weight of the bulk solids.

The plumb bob system can determine the height of bulk solids below the surface of water or liquids.

Due to newer technologies and measuring methods, level measurement with a plumb bob is hardly up to date.

Find out more about level measurement with plumb bob sensors and more innovative solutions here:

Contact and non-contact level measurement

The selection of the suitable measuring principle is first made according to the application and the application-specific criteria.

The measuring principles differentiate between the criteria "non-contact" and "contact".

Non-contact sensors do not have to be installed in the tank or storage tank, but can also measure through walls. This is the case with hazardous substances. They also have the advantage that they require a special tank design for longer measuring distances. They also have a low susceptibility to interference.

On the other hand, non-contact methods have limited installation options because the technology between the transmitter and receiver requires a clear view of the medium. Installations also make the measurement of non-contact methods more difficult.

Our level switches are characterised by their robustness and functional reliability, which makes them particularly suitable for use in silos with aggressive atmospheres and high temperatures. They are the preferred measuring technology in industries such as chemicals, food production and the processing of raw materials such as sugar, salt, grain, lime, pellets and cement.